Calcium carbide is a chemical compound with the chemical formula CaC2. It is a grayish-white crystalline solid used in producing acetylene gas in various industrial applications, including welding and cutting torches, and as a fuel for lighting and heating.

Calcium Carbide Manufacturing Process:

- Raw Material Preparation: We begin by carefully blending lime (calcium oxide) with coke (carbon) in precise proportions to prepare the charge for production.

- Carbothermic Reduction: The prepared mixture is then introduced into an electric arc furnace. Here, a high-temperature electric arc facilitates the carbothermic reduction reaction, transforming the mixture into calcium carbide and carbon monoxide.

- Reaction: Within the furnace, the following reaction occurs: CaO + 3C → CaC2 + CO, resulting in the formation of calcium carbide and carbon monoxide gas.

- Cooling: Post-reaction, the furnace contents are allowed to cool, solidifying the calcium carbide.

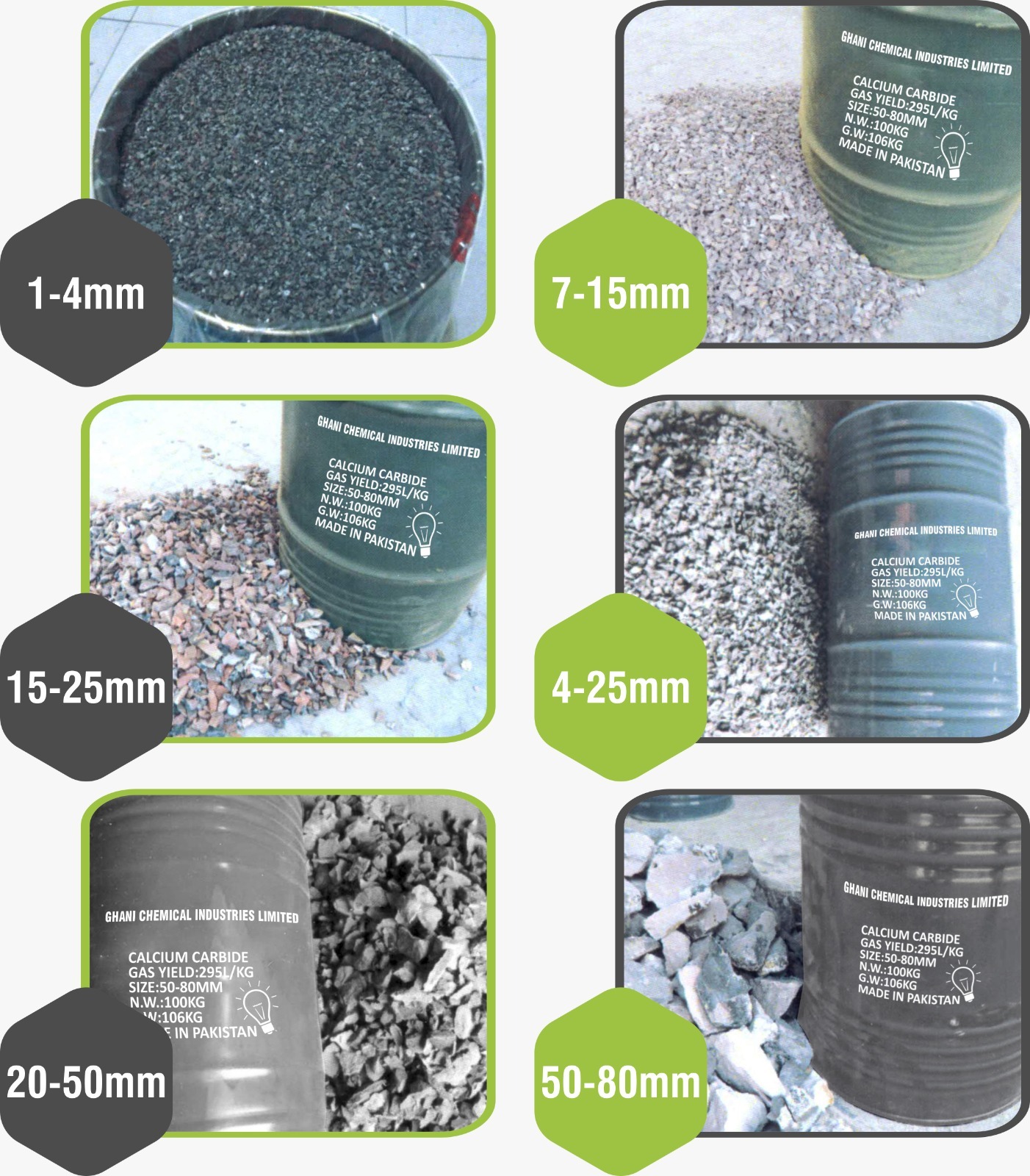

- Crushing and Screening: The solidified calcium carbide is then crushed and screened to achieve the desired particle sizes.

- Packaging: Finally, the processed calcium carbide is packaged for distribution, ready for its various industrial applications.